Warehoue Storage Double Deep Pallet Rack

Basic Info

| Model NO. | PR 90 |

| Usage | Warehouse Rack |

| Material | Steel |

| Structure | Rack |

| Type | Selective Pallet Racking |

| Mobility | Adjustable |

| Height | 5-15m |

| Weight | 500kg-2000kg |

| Closed | Semi-closed |

| Development | Conventional |

| Serviceability | Common Use |

| Beam Deflection | 1/200 |

| Forklift | Double Deep |

| Accessories | Pallet Support Bar |

| Norm | Fem 10.2.02 |

| Transport Package | Packed in Bundles on Pallets Wrapped with Films |

| Specification | upright 1.8--2.5mmT, Beams 1.5-1.8mmT |

| Trademark | calin |

| Origin | Jiangsu, China |

| HS Code | 73089000 |

| Production Capacity | 20, 000 Tons Per Year |

Product Description

1. Product Description:Warehoue Storage Double Deep Pallet Rack is similar to selective racking; but pallets are now stored two rows deep instead of one. This type of racking therefore requires specialised pallet handling equipment using ether a specialised forklift or a standard unit a with double deep handling attachment.

The most common forklift used for double-deep handing is a reach truck. One key disadvantage with reach trucks is that they require a counterbalance for loading and unloading the pallet onto trucks, which can double capital investment requirements for your pallet handling equipment.

2. Basic Components:

Selective pallet racking is composed of basic element such as frames and beams. It also consists of a full range of accessories to fulfill all of your requirements. The system is designed for the optimized storage of goods of all sizes and weights.

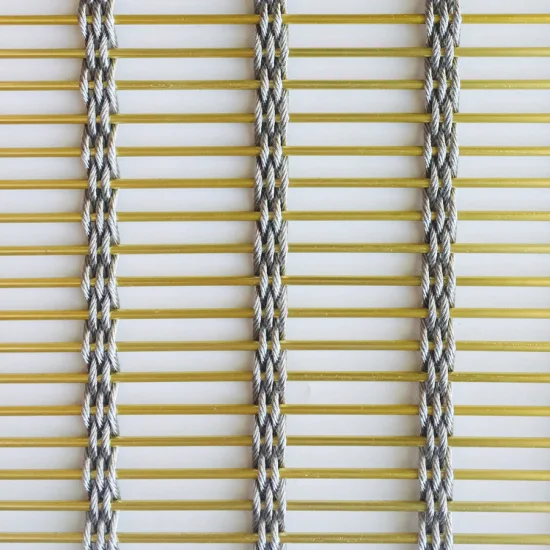

The finish of all painted parts is an Epoxy-powder coating polymerized at 180 °C.

The standard colors are RAL 5015 (= sky blue) for the frames and RAL 2004 (=pure orange) for the beams. Protectors are painted in RAL 1004 (= golden yellow). Some smaller parts have a galvanized finishing. Special colors are available on request.

3. Product Specifications:

Beam Loading Chart:

| Beams Specification | Clear Entry (mm) Deflection<1/200 | |||||||||

| 1500 | 1800 | 2000 | 2300 | 2500 | 2700 | 3000 | 3300 | 3600 | 3900 | |

| B80*50*1.5 | 4000 | 2800 | 2200 | 1700 | 1500 | 1200 | 1000 | 850 | ||

| B100*50*1.5 | 4200 | 3400 | 2800 | 2500 | 2100 | 1700 | 1400 | 1200 | ||

| B110*50*1.5 | 4500 | 3300 | 2800 | 2500 | 2200 | 1800 | 1500 | 1200 | ||

| B120*50*1.5 | 4000 | 3400 | 3000 | 2600 | 2200 | 1800 | 1500 | |||

| B140*50*1.5 | 4500 | 3800 | 3200 | 3000 | 2600 | 2000 | ||||

| B160*50*1.5 | 4800 | 4200 | 3800 | 3300 | 2800 | |||||

4. Advantages and Key benefits·

Advantages

- Lowers capital investment compared to scissor & pantograph masts.

- Reduces required aisle width when compared to manual fork extensions

- Increases handling of pallets and reduces stock damage compared to manual fork extensions.

- Clear visibility, no extra obstructions because of all extra moving parts of the scissor reach system.

Disadvantages

- Reduces forklift lifting capacity

Pallet Access (LIFO)

Double-Deep is Last In First Out (LIFO). This type of racking reduces the amount of accessible stock keeping units (SKU's) due to 50% of SKU's being behind pallets when storage locations are at full capacity. Can increase pallet storage by as much as 10-15% depending on racking layout.

Double-deep is better suited to stock that has a medium to long term shelf life. Highly perishable goods aren't recommended for this style of racking due to LIFO racking type.

5. Factory Production:

Roll forming--Welding--Pretreatment-Powder-Coating--Baking--Off loading--Packing

6. RFQ Documents:

Before you send us your requirement for quotation, please prepare the following information:

Warehouse layout CAD drawings if available.

Pallet size, entry side, width, depth, height of goods.

Loading weight per pallet.

Clear height of the warehouse

Your forklift information, working aisles width and max. Reaching height.

Your intra logistic flow within the warehouse.