Industrial Warehouse Heavy Duty Pallet Flow Fifo Rack Manufacturer

Basic Info

| Model NO. | FR90 |

| Weight | 150-1500kg |

| Closed | Closed |

| Development | New Type |

| Serviceability | for Special Purpose |

| Slope of Roller Bed | with 3-5° |

| Roller Diameter | 60mm |

| Load Per Roller | 150kg/Roller |

| Finish | Galvanized |

| Transport Package | Packed in Standard Pallets and Wrapped with Films |

| Specification | tailor made |

| Trademark | calin |

| Origin | Jiangsu, China |

| HS Code | 73089000 |

| Production Capacity | 5000 Tons Per Year |

Product Description

1. Product Description:Industrial Warehouse Heavy Duty Pallet flow FIFO Rack, also known as Gravity flow rack, Pallet Flow systems. It fully utilize the available storage space while ensuring the faces along the picking aisle remain regularly stocked. In this first-in/first-out (FIFO) system, pallets are loaded at the top end of the slightly inclined rack and slide safely and effortlessly at a controlled pace to the other side.

These heavy-duty pallet flow systems are designed for years of trouble-free operation with rugged load-bearing wheels. Inventory turnover is quick and efficient, whether merchandise is moved strictly on pallets or as part of an order picking system.

2. The basic components

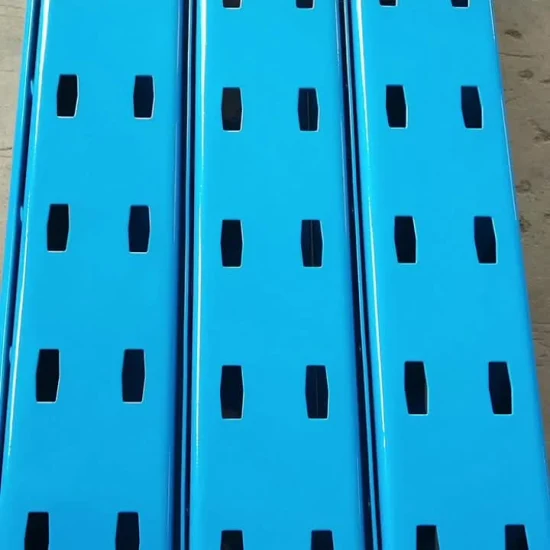

2.1 Industrial Warehouse Heavy Duty Pallet flow FIFO Rack is composed of frames, beams and roller bed. The roller bed consists of a set of rollers designed to fit into a frame structure and mounted on the loading beams. To avoid the fast sliding down of pallets, normally brake rollers are designed. There is also one set of pallet separator for picking the first pallet. The system is designed for the storage of first in first out operation.

2.2 The roller bed is composed of a number of unpowered rollers, C section frames, brake rollers, entry guide and pallet separators:

The roller bed are made into standard modules and connected by bolts and nuts.

Unpowered roller features:

1,Standard 300/1800 rollers2,Loading of roller: 50-300kg/pcs 3,Maintenance free4,Bearings: Sturdy and Durable5,waterproof, dust free6,long life spanRoller Loading Chart:

2.3 Pallet Separators:

e

2.4 Brake rollers.

For the safety operation of flow rack, the brake rollers are installed on the flow bed to reduce the sliding speed of the pallets.

3. Product Features:

| Model NO.: | FR 90 | Material: | Steel Q235B |

| Origin: | Jiangsu, China | Trademark: | CALIN |

| Roller Diameter: | 60 mm | Load per roller: | 150kg/roller |

| Pallet separator | Yes | Payment Terms | T/T, L/C |

| Delivery deadline: | 3-4 weeks | Certificate: | ISO 9001 |

| Type: | Flow Rack system | HS Code: | 73089000 |

| Usage: | Warehouse Rack | Finish treatment: | Powder Coated |

| Slope of Roller bed | 2.5--4 degree | Loading Capacity | 500kg-1500kg |

| MOQ | 1 20' container | Port: | Shanghai Port |

| Transport Package: | Packed on Pallets and wrapped with Films |

4. Factory Production:

5. RFQ documents:

Before you send us your Requirement For Quotation, please prepare the following information:Warehouse layout CAD drawings if available.

- Pallet size, entry side, width, depth, height of goods. specially the underneath structure of the pallets. We suggest better to have a sample of pallets for testing of slidiing on rollers.

- Loading weight per pallet.

- Clear height of the warehouse

- Your forklift information, working aisles width and max. reaching height.

- Your intra logistic flow within the warehouse.

6.Packaging and Delivery:

1).Packaging details: Standard export package.

Long profiles are packed in bundles on plywood or steel pallets, and covered by plastic films. Between each package, air bags are also filled if necessary. For the thinner material such as steel decking, Edge protectors are applied. The small accessories and fasteners are packed inside of the carton boxes and fixed on pallets.

2).Delivery time: For the standard products, Our delivery time is 3 weeks after receipt of the 30% deposit. Other special application of racks can be delivered within 4-5 weeks.

CALIN serves "Total Storage Solutions" through our wide products categories ranging from Selective Pallet Racking, Shelving System, Semi-automated and full automatic warehouse storages solutions. We have over 20 years of experience and expertise, in collaboration with our customers, to provide better solutions. Our expert engineer team are able to create a layout by using the latest AutoCAD software and deliver tailor-made proposal, so as to meet your exact storage and logistics needs.

We do manufacture and deliver out racking products, but more importantly, we also provide a total package services including consulting, planning and maintenance. No matter different amounts of your projects are, we fairly value at your every simple and complicated project for customers' rights. Our Customer Service will insure that your order can be delivered on time with satisfaction.

parators: